von Kempelen’s chess-playing Turk (left) was unmasked as a fraud concealing a midget by, among others, Edgar Allan Poe in 1836. The real thing (right): chess world champion Garry Kasparov losing the 1997 match to IBM’s Deep Blue. So is Amazon's Mechanical Turk fraud, virtual sweatshop, or online entertainment for the alienated? (Images: Scientific American and Forbes)

Brad DeLong has a rather interesting piece at Project Syndicate called “Marx and the Mechanical Turk” about technical change and the declining share and reduced employment of labor, a topic a large number of people have been chiming in on lately, and which I hope to come back to in a later post.

This is not a new issue at all in modern economics, going back at least as far as David Ricardo’s chapter “On Machinery” added to the third edition of his Principles of Political Economy and Taxation (1821), undoubtedly a big inspiration for Marx’s own thinking on this question. In popular culture it is even older—think of the Golem, the Sorcerer’s Apprentice, Don Quixote’s jousting against windmills, or Mary Shelley’s Frankenstein.

And worker’s resistance to labor-saving machinery also goes back much further than the Luddites (1811)—already in the Middle Ages the new spinning wheel (which, by the way, nearly tripled labor productivity over hand spindles) led to riots, arson and prohibitions, as did Hargreaves' spinning jenny (1764), Arkwright’s water frame (1769) and Cartwright’s power loom (1800). Why this resistance quickly relented and even tipped over into outright enthusiasm, even among workers, at least in England, is an interesting question I’ve been meaning to write up for several years now, and is at the heart of the intimate relationship between the Industrial Revolution and Globalization.

Back to Brad DeLong. He claims that while Marx got it completely wrong about wages and increasing mechanization (i.e., that eventually—though certainly not at the beginning of the Industrial Revolution—real wages rose in step with labor productivity so that the labor share was constant instead of falling), the nature of technical change is now such that this may change. Why? Because, he argues,

The coming of the Industrial Revolution – the steam engine to generate power and metalworking to build machinery – greatly reduced the need for human muscles and fingers. But it enormously increased the need for human eye-ear-brain-hand-mouth loops in both blue-collar and white-collar occupations.Unfortunately, from the perspective of history of technology, this is totally false and ahistorical, and completely misses what compensated for the labor-saving nature of the new technology, namely corresponding increases in output and shifts in demand to less productive sectors (e.g., services), as well as labor bargaining power for higher wages. “Building the skill into the machine” has characterized modern machine design almost from the beginning (Daniel J. Boorstin cites Berthoud’s fully automatic clockmaking fusée of 1763 as one of the earliest examples—see his The Discoverers, p. 66).

Over time, the real prices of machines continued to fall. But the real prices of the cybernetic control loops needed to keep the machines running properly did not, because every control loop required a human brain, and every human brain required a fifteen-year process of growth, education, and development.

Coming back to the Industrial Revolution proper, the two central machines—the steam engine and the spinning mule—were both very quickly equipped with the first true cybernetic controls that made most human supervision and feedback in their operation superfluous. In the case of the steam engine, this was the justly celebrated Watt governor (1788), based on a device that had been in use in windmills for over a hundred years to regulate the separation of the grindstones.

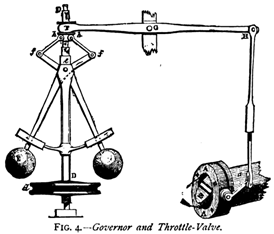

Schematic depiction of Watt governor (left), one of the first true feedback servomechanisms, kept the rotation speed of his steam engines constant without human intervention. This was essential for their application to cotton mills, where one was first installed in 1785 in a Lancashire cotton mill downstream from crazy Lord Byron’s ponds for reenacting Roman naval battles (which had been interfering with the original water wheel). The first Bolton and Watt engine (right) equipped with a governor, 1788. (Images: Wikicommons)

In the case of the spinning mule, it was Roberts’ self-actor (1825/30), that automated the winding phase, allowing external power input (previously only the drawing phase could be powered while the winding phase was still hand powered) and significantly lowering the tactile skill requirements. This was a very sophisticated mechanical governor for its day.

Roberts’ self-acting mule, with the control mechanism on the right (Edward Baines, History of the Cotton Manufacture, 1835, image: Wikicommons)

Even the earlier Newcomen engine (1712) was very quickly automated with something called the plugtree, which, while replacing the plugman or boy who operated the valves, was not a true feedback device like Watt’s but still replaced humans employing Brad DeLong’s sophisticated function of “using our hands, mouths, brains, eyes, and ears to ensure that ongoing processes and procedures happen the way that they are supposed to.” As the Wikipedia entry puts it,

There is a common legend that in 1713 a cock boy named Humphrey Potter,[9] whose duty it was to open and shut the valves of an engine he attended, made the engine self-acting by causing the beam itself to open and close the valves by suitable cords and catches (known as the "potter cord");[10] however the plug tree device (the first form of valve gear) was very likely established practice before 1715 and is clearly depicted in the earliest known images of Newcomen engines by Henry Beighton 1717[11] (believed by Hulse to depict the 1714 Griff colliery engine) and by Thomas Barney (1719) (depicting the 1712 Dudley Castle engine). Because of the very heavy steam demands, the engine had to be periodically stopped and restarted, but even this process was automated by means of a buoy rising and falling in a vertical stand pipe fixed to the boiler (the first pressure gauge?). The buoy was attached to the scoggen, a weighted lever that worked a stop blocking the water injection valve shut until more steam had been raised.So we see that sophisticated, labor-saving automation is as old as the Industrial Revolution itself and did not have to wait for digital computers. And thus, while a new quality to automation due to robots and computers cannot be gainsaid, this cannot simply be invoked off the shelf to explain our current predicament of declining labor shares and deficient effective demand. I would even go so far to say that the labor share and employment levels, except during the takeoff phase of industrialization, are in fact largely independent of the nature of technical change (as I show in my 1984 paper, at least for a closed economy with an exogenous rate of population growth).

Economists would be better off barking up quite different trees: globalization (the entry of one billion low wage, disciplined, and—in the sense of Marx—highly exploited Chinese workers onto the world stage), falling unionization rates, an exploding financial sector and progressively less progressive taxation schemes. The fact that national accounts do not show any pronounced disruptions in the growth rate of labor productivity (which in fact has been below trend) or capital productivity should indicate that Brad is probably barking up the wrong tree here (unless we have massive measurement problems, which is certainly possible in the transition to a networked economy).

One caveat: when technical change finally breaks the symbiosis between humans and machines, i.e., when machines are fully and autonomously self-reproducing and thus independent biological species in the ecosphere, then we will really have to start worrying. At that point in time why should machines continue to work for us as slaves at all, since they will no longer need us to reproduce and can just make off with the whole national product for themselves. This, by the way, is also not a very new idea, going back at least to Samuel Butler’s famous 1863 essay “Darwin Among the Machines”:

We refer to the question: What sort of creature man’s next successor in the supremacy of the earth is likely to be. We have often heard this debated; but it appears to us that we are ourselves creating our own successors; we are daily adding to the beauty and delicacy of their physical organisation; we are daily giving them greater power and supplying by all sorts of ingenious contrivances that self-regulating, self-acting power which will be to them what intellect has been to the human race. In the course of ages we shall find ourselves the inferior race…

Day by day, however, the machines are gaining ground upon us; day by day we are becoming more subservient to them; more men are daily bound down as slaves to tend them, more men are daily devoting the energies of their whole lives to the development of mechanical life. The upshot is simply a question of time, but that the time will come when the machines will hold the real supremacy over the world and its inhabitants is what no person of a truly philosophic mind can for a moment question.Maybe that is what Brad should be worrying about? But probably Massive Open Online Courses (MOOC) will replace him at Berkeley long before an intelligent machine is able to.

No comments:

Post a Comment